ほとんどの場合、人々が何かが非常に正確であると言うとき、またはそれが高度な精度を持っていると言うとき、彼らは同じことを意味します。日常のスピーチでは、精度と精度は比較的互換性があります。

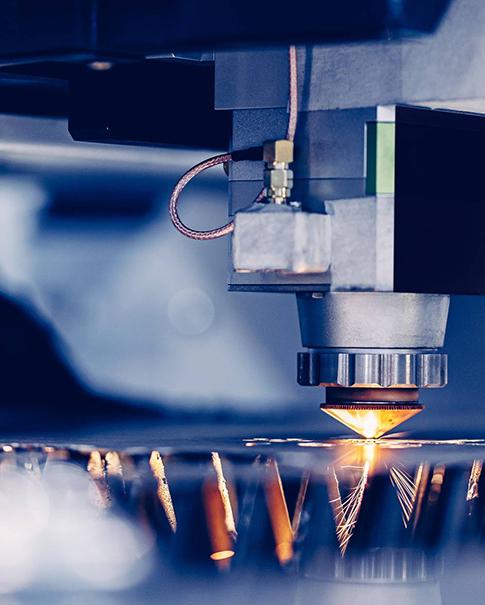

ただし、科学的または技術的な観点から、正確性と精度は実際には2つの異なる品質を指します。この記事では、精度と精度の違いについて説明し、CNC加工にどのように適用するかについて説明します。

測定値がその測定の理論的に正しい値にどれだけ近似するかの説明。

言い換えれば、科学者とエンジニアは精度を使用して、単一の測定値が真の、受け入れられた、またはターゲットの価値と一致するかを示します。

精度と精度を説明するために使用される古典的な例は、ブルズアイのターゲットです。精度は、測定値が希望の値であるブルズアイの中心にどれだけ近いかを表します。

目的の値または真の値に近い値は、中心の上、下、または中心の側面に着陸するかどうかにかかわらず、比較的正確であると見なされます。正確であるための重要な品質は、正しい値に近いことです。

の科学的定義 精度 は:

測定値のコレクションが互いにどれだけ近いかの説明。

精度は、データセットの分散範囲、またはデータポイント間の広がりを表します。

ブルズアイの例では、複数の測定値がブルズアイの中心の下にクラスター化されている場合、それらは正確なデータセットです。しかし、彼らはブルズアイの中心にないため、それほど正確ではありません。

しかし、測定値がすべてブルズアイの中心に焦点を合わせている場合、それらは両方とも正確かつ正確であると言えます。

ブルズアイの例は人気がありますが、それが製造および製造アプリケーションにどのように関連するかを理解するのは難しい場合があります。機械加工の精度と精度の違いは、部品のバッチがCADモデルまたは設計の青写真とどの程度密接に一致するかに関連しています。

非常に正確なCNC加工装置は、設計モデルに非常に密接に一致する部品を生成できます。たとえば、パーツ設計では、幅0.50インチのペアx 5.00インチの長いスロットがその表面に機械加工されており、スロットは2.0インチ離れていると仮定します。

高品質のスペシャリストが単一の完成した部品を調べると、半インチのスロットが実際に5.05インチの長さに切断され、1.96インチの間隔でしか離れていなかったことを測定します。機械加工された部分が設計モデルを正確に表すかどうかを判断するのは、質の高い専門家の仕事です。この部分が拒否されているかどうかは 許容耐性 デザインに組み込まれています。

加工の観点から、精度は、製造された部分が設計モデルとどの程度密接に一致するかを反映していますが、精度はその部分を何度も作成するときに再現性を示します。

デザイナーは、製造された部品に期待を満たすか、それを超えることを望んでいます 機械加工許容範囲。これは、精度と精度の両方で部品を生産できる機器またはベンダーを見つけることを意味します。

Safekesoはまさにそれを提供しています。品質と信頼性に対する私たちの評判は、あらゆる注文でデザインの仕様内で顧客に部品を提供するために一生懸命働いていることを意味します。次のデザインを製造するために機械工場が必要な場合は、世界クラス CNC加工サービス 手頃な価格で部品を迅速に手に入れるのに役立ちます。